Main Console

- Windows base CNC control system

- Remote maintenance.

- Huge order saving.

- Trouble-shooting.

- Optimized order memory.

- Production and order management.

- Available to connect with the customer internal ERP.

Feeder

- Operation can be controlled by both main console and each unit touch screen.

- Lead-edge feeding, adjustable air control, precious registration

- Precious liner guideway lateral moving

- Motorized side squaring and paper support

- Powerful dust remover, with anti-static bar, centralized dust collection, less ECT loss

Printer

- Operation can be controlled by both main console and each unit touch screen.

- Top print, high precious transfer structure with ceramics vacuum transfer wheel, good registration accuracy.

- Quick printing plate mounting, motorized phase zero.

- Ink saving circulate system, safety ink taking, short ink alarm.

- Option: Double doctor blade

Drying

- Operation can be controlled by both main console and each unit touch screen.

- Vacuum transfer, motorized gap adjustment.

- Energy saving dry section, hot air circulating, settable temperature.

- Option: Infrared ray or UV dryers

Slotter

- Operation can be controlled by both main console and each unit touch screen.

- Liner guideway lateral moving device with universal cross joints.

- Pre-creaser, creaser slotting holder motorized gap control.

- Box height motorized control

- Large displacement of middle knife.

Diecutter

- Up die-cutting, clean up scrap thoroughly, motorized die-cutting pressure adjustment.

- Die-cutting roll pneumatic self-locking device, smooth die-cutting.

- Sheet guide roll displacement motorized control, quick order change.

- C.U.E quick change die-cut anvil with grinding mechanism.Precious settable speed difference compensation, ensure die-cutting accuracy.

- Servo driven control

Folder Gluer

- Fully automatic process. Stable and precise

- Vacuum transport belt

- Independent forming belt drives

- Motorized adjusting gauging rollers

Top Counter Ejector

- Friction-free top stacking minimizes fish tailing

- Reliable stacking on Diecut and Outside Glue boxes

- Perfect counting at high speed

- Servo drivers system for precise bundle control

INOVA 16.32 Flexo Folder Gluer (Top print)

Metric

US / Imperial

Processed materials *

Corrugated board

1.4 to 10 mm

1/16 to 25/64 in

Corrugated flute type

E, B, C, A, EF, EB, BC, AC, AB

Capability

Sheet size width

795 to 3245 mm

31 5/16 to 127 3/4 in

Speed

max

10800 b/h

10800 b/h

Slotting blade thickness

7.5 mm

5/16 in

Printing

Printing size width

max

3150 mm

124 in

Print cylinder circumference

1676 mm

66 in

Sheet sizes

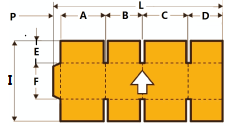

Sheet length "L"

795 to 3245 mm

31 5/16 to 127 3/4 in

Total length of panels "H"

max

3150 mm

124 1/64 in

Sheet width "l"

420 to 1560 mm

16 1/2 to 61 7/16 in

Small panel "A=C"

normal

160 to 1440 mm

6 5/16 to 56 11/16 in

reverse

70 to 1350 mm

2 3/4 to 53 1/8 in

Large panel "B=D"

normal

160 to 1440 mm

6 5/16 to 56 11/16 in

reverse

250 to 1530 mm

9 7/8 to 60 1/4 in

Half-box "B+C"

normal

380 to 1600 mm

15 to 63 in

reverse

410 to 1600 mm

16 1/8 to 63 in

Slotting length "E"

max

730 mm

28 3/4 in

Box height "F"

min

100 mm

3 15/16 in

Lap width "P"

35 to 50 mm

1 3/8 to 2 in

Unfolded sheet

max

1800 mm

70 7/8 in

Dimensions & weight

Length **

23.6 m

77 ft

Width

6.85 m

22 ft

Height

3.43 m

11 ft

Net weight **

68000 kg

149900 lbs

Installation

Electrical connected load **

233 KVA

233 KVA

* Processed materials may vary with material property.

** The estimates are base on an example of machine composition : 4CSD+FG

INOVA 16.32