Lead Edge Feeder

- From E micro flute to BC double wall board

- Roll-to-Roll transfer with dust cleaner

- Optional: Vacuum transfer with “No-Crush Feed” more powerful dust cleaner with static-free, rotary brushing and dust blowing

Printer

- Accurate top printing with vacuum transfer

- Dual-chambered doctor blade inking system

- Smart ink circulation recovery and washing system

- Print plate thickness from 4.2 mm to 7.2 mm

- Optional: NOVO 10.25 with Roll-to-Roll Transfer

Slotter

- 3 pairs of shafts with 5 motorized heads, including

- one Big Pre-crease, one Crease and one Slot

- Big Pre-Crease features better folding accuracy, and minimizes score cracking

- Movable central slotting blade

Rotary Die Cutter

- Accurate die-cutting with anvil grinding and

- Anvil speed compensation by +/- 3 mm

- Side to side oscillation of anvil cylinder 50 mm

- Optional: Instant die mounting system

Gluing Unit (Valco System)

- Valco glue spraying adhersive system for one side is optional

- Extra cost may apply for two side Valco system

Folder Gluer

- Fully automatic process. Stable and precise

- Vacuum transport belt

- Independent forming belt drives

- Motorized adjusting gauging rollers

Top Counter Ejector

- Friction-free top stacking minimizes fish tailing

- Reliable stacking on Diecut and Outside Glue boxes

- Perfect counting at high speed

- Servo drivers system for precise bundle control

NOVO 10.25 Flexo Folder Gluer (Top print)

Metric

US / Imperial

Processed materials *

Corrugated board

1.2 to 10 mm

3/64 to 25/64 in

Corrugated flute type

E, B, C, A, EF, EB, BC, AC, AB

Capability

Sheet size width

610 to 2540 mm

24 to 100 in

Speed

max

18000 b/h

18000 b/h

Slotting blade thickness

7.5 mm to 9.52 mm

5/16 to 3/8 in

Printing

Printing size width

max

2400 mm

94 1/2 in

Print cylinder circumference

1067 mm

42 in

Sheet size

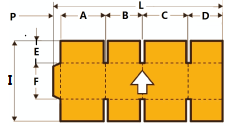

Sheet length "L"

610 to 2540 mm

24 to 100 in

Total length of panels "H"

max

2510 mm

98 13/16 in

Sheet width "I"

265 to 980 mm

10 7/16 to 38 9/16 in

Small panel "A=C"

normal

145 to 1105 mm

5 11/16 to 43 1/2 in

reverse

60 to 1020 mm

2 3/8 to 40 1/16 in

Large panel "B=D"

normal

145 to 1105 mm

5 11/16 to 43 1/2 in

reverse

230 to 1190 mm

9 1/16 to 46 7/8 in

Harf-box "B+C"

normal

290 to 1250 mm

11 7/16 to 49 3/16 in

reverse

320 to 1250 mm

12 5/8 to 49 3/16 in

Slotting length "E"

max

445 mm

17 1/2 in

Box height "F"

min

90 mm

3 9/16 in

Lap width "P"

30 to 45 mm

1 to 1 3/4 in

Unfolded sheet

max

1700 mm

66 15/16 in

Dimensions & weight

Length **

21.7 m

71 ft

Width

5.65 m

19 ft

Height

3.08 m

10 ft

Net weight **

61000 kg

134500 lbs

Installation

Electrical connected load **

178 KVA

178 KVA

* Processed materials may vary with material property.

** The estimates are base on an example of machine composition : 4CSD+FG

NOVO 10.25